#Laboratory Desiccator

Explore tagged Tumblr posts

Text

How Desiccator Cabinets Help Prevent Contamination and Extend Shelf Life

Introduction: Understanding the Importance of Desiccator Cabinets in Preventing Contamination and Extending Shelf Life

Contamination control and shelf life extension are paramount concerns for industries that rely on preserving product integrity. In this article, we delve into the crucial role played by desiccator cabinets in safeguarding the quality and shelf life of various products. By creating a controlled environment with low humidity levels, desiccator cabinets effectively prevent moisture-related contamination and degradation. We will explore the science behind contamination control and shelf life reduction, provide an overview of desiccator cabinet functionality and design, discuss factors to consider when choosing the right cabinet, offer maintenance best practices, present real-life case studies, highlight emerging trends in desiccator technology, and underline the significance of desiccator cabinets in upholding product quality and prolonging shelf life.

Introduction: Understanding the Importance of Desiccator Cabinets in Preventing Contamination and Extending Shelf Life

Exploring the significance of contamination prevention and shelf life extension

When it comes to storing sensitive materials, such as chemicals, pharmaceuticals, or electronic components, preventing contamination and extending shelf life are of utmost importance. Enter the unsung hero of storage solutions – desiccator cabinets. These seemingly ordinary cabinets play a critical role in maintaining product quality and ensuring that your investments don't go to waste.

The Science Behind Contamination Control: Exploring the Factors that Affect Product Quality and Shelf Life

Understanding the key factors contributing to contamination and shelf life reduction

To fully grasp the importance of desiccator cabinets, it's essential to understand the science behind contamination control and shelf life reduction. Factors such as moisture, humidity, oxygen, and particulate matter can significantly degrade product quality over time. Moisture, for instance, can lead to chemical reactions, mold growth, or corrosion, while oxygen can accelerate the oxidation process and compromise the integrity of delicate components. By addressing these factors, desiccator cabinets help to mitigate contamination risks and extend the shelf life of stored materials.

Desiccator Cabinets: An Overview of their Functionality and Design

How do desiccator cabinets work?

Common features and components of desiccator cabinets

Desiccator cabinets, with their simple yet ingenious design, provide a controlled environment that minimizes moisture, humidity, and oxygen exposure. These cabinets are typically airtight and equipped with desiccants, such as silica gel or activated charcoal, to absorb any moisture or volatile gases present in the storage area. By removing or reducing these elements, desiccator cabinets help maintain dry and oxygen-free conditions, thus safeguarding the quality and integrity of stored materials. Common features include adjustable shelves, clear viewing windows, and air-tight seals to ensure maximum effectiveness.

Choosing the Right Desiccator Cabinet: Factors to Consider for Optimal Contamination Prevention

Identifying the specific needs of your application

Key considerations when selecting a desiccator cabinet

When selecting a desiccator cabinet, it's crucial to consider the specific needs of your application. Factors such as the type of materials being stored, required storage capacity, and the level of contamination control required should all be taken into account. Additionally, factors like durability, ease of maintenance, and regulatory compliance should also influence your decision. By carefully assessing these considerations, you can choose a desiccator cabinet that perfectly matches your requirements and helps prevent contamination effectively.

Remember, desiccator cabinets may not have the glamour of high-tech gadgets, but they play a vital role in maintaining the quality and extending the shelf life of your valuable materials. So, give them the credit they deserve and invest in the right desiccator cabinet to safeguard your products and your brand's reputation.

Desiccator Cabinet Maintenance and Best Practices: Ensuring Longevity and Effectiveness

Proper cleaning and maintenance guidelines

Keeping your desiccator cabinet clean and well-maintained is crucial for its longevity and effectiveness in preventing contamination and extending shelf life. Here are some guidelines to follow:

1. Regularly clean the interior and exterior of the cabinet using a mild detergent or cleaning solution. Avoid using abrasive cleaners that could damage the cabinet's surfaces.

2. Ensure that the desiccant material inside the cabinet is replaced or regenerated as per the manufacturer's recommendations. This helps to maintain the cabinet's moisture-absorbing capabilities.

3. Inspect the cabinet for any signs of wear or damage. Replace worn-out seals or gaskets to ensure a tight seal and optimal performance.

4. Keep the cabinet away from direct sunlight or extreme temperatures, as these can affect its performance.

Tips for maximizing the effectiveness of desiccator cabinets

To get the most out of your desiccator cabinet, consider these tips:

1. Organize your items properly inside the cabinet. Place them in sealed containers or bags to prevent moisture from entering.

2. Limit the frequency and duration of cabinet openings to minimize moisture ingress. Plan ahead and retrieve all necessary items in one go whenever possible.

3. Use a hygrometer inside the cabinet to monitor and maintain the desired humidity level. Adjust the desiccant or drying agent as needed to ensure optimal moisture control.

4. Consider adding a backup desiccant or a moisture indicator to provide an extra layer of protection and early warning for moisture levels.

Remember, a well-maintained and properly used desiccator cabinet is your ally in controlling contamination and preserving the shelf life of your products.

Case Studies: Real-Life Examples of How Desiccator Cabinets Have Helped Extend Shelf Life and Maintain Product Integrity

Case study 1: Desiccator cabinet implementation in the pharmaceutical industry

In a pharmaceutical manufacturing facility, the implementation of desiccator cabinets proved instrumental in extending shelf life and maintaining product integrity. By storing sensitive items, such as medications and diagnostic reagents, in desiccator cabinets, the company was able to effectively control the moisture levels and prevent degradation.

Not only did this result in longer shelf life for the products, but it also ensured their efficacy and reliability when used by healthcare professionals. This case study showcases the critical role desiccator cabinets play in safeguarding the quality of pharmaceutical products.

Case study 2: Desiccator cabinet usage in the electronics manufacturing sector

The electronics manufacturing sector faces unique challenges in preventing contamination and maintaining the performance of sensitive components. Desiccator cabinets have proven to be a valuable asset in this industry.

By storing electronic components in desiccator cabinets, manufacturers can protect them from moisture and other contaminants that can compromise their functionality. This has led to improved product reliability, reduced failure rates, and increased customer satisfaction. The case study highlights the importance of desiccator cabinets in ensuring the quality and longevity of electronic products.

Future Trends: Advancements in Desiccator Technology and Their Implications for Contamination Control

Exploring emerging technologies in desiccator cabinets

As technology continues to advance, so does the field of desiccator cabinets. Manufacturers are constantly exploring innovative solutions to enhance contamination control and extend shelf life. Some of the emerging technologies include:

1. Smart desiccator cabinets equipped with sensors and IoT capabilities to monitor and regulate humidity levels automatically.

2. Advanced desiccant materials that offer a higher moisture-absorbing capacity and longer regeneration cycles.

3. Desiccator cabinets with integrated air purification systems to filter out airborne contaminants.

Potential benefits and impact on contamination control and shelf life extension

These advancements in desiccator technology have the potential to revolutionize contamination control and shelf life extension. By utilizing smart cabinets and advanced desiccants, industries can achieve more precise moisture control, reducing the risk of product degradation.

The integration of air purification systems further ensures a pristine environment for sensitive items. Overall, these advancements promise enhanced product quality, longer shelf life, and a higher level of confidence in the integrity of stored materials.

Conclusion: Emphasizing the Role of Desiccator Cabinets in Safeguarding Product Quality and Shelf Life

Desiccator cabinets are not just fancy boxes with fancy names; they are essential tools for preserving product quality and extending shelf life. By effectively controlling moisture and preventing contamination, desiccator cabinets play a vital role in various industries, including pharmaceuticals and electronics.

With proper maintenance and adherence to best practices, these cabinets can continue to safeguard the integrity of sensitive items and ensure their optimal performance. As technology advances, we can expect even more innovative solutions that will further enhance the role of desiccator cabinets in contamination control and shelf life extension.

So, the next time you encounter a desiccator cabinet, remember its importance in protecting your products from moisture and contamination. Trust in this unsung hero and let it work its magic in preserving the quality and extending the shelf life of your valuable items.

Original Sources: https://globallabsupply.blogspot.com/2023/07/how-desiccator-cabinets-help-prevent.html

0 notes

Text

Been working on a Spelljammer setting, finished sketching out the overview of one of the three stars in this particular Crystal Sphere. Send asks about them if you want :3

Cervinus Wildspace

Past the heady days of world and sphere defining empires, this star hosts the 3 primary life bearing planets of the Sphere. By weight of population and matured biospheres, they tend to have the most influence and economic might. None are fully unified, but they have significant polities that can project power beyond their atmospheres. Trade in organics, food, high quality magical items are all centered around these worlds. The balance of power between the inhabited worlds and their leading nations is sometimes delicate, but tends to keep most serious conflict in the realm of political intrigue and saber rattling, rather than outright war. The major powers each have some modest fleets of military and courier spelljammers for defense and surveying work, with a varying mix of private and mercantile traffic tying them together. While they have a number of outposts and asteroid/lunar settlements, none have much control beyond their orbital volumes.

Stellar Objects:

Cervinus: Typical orange star, Cervinus is the center of this part of Triadspace, around which 10 worlds orbit in steady clockwise rotations.

Elysium: Earth type, Size D, very hot, millions of inhabitants, Tomb World, Altered Humanity (undead)

The Workings that once made this world an eternal summer paradise of endless farms, gardens and noble estates have long since guttered out. What remains now are creeping wastes and deserts, the bones of dead cities swathed in desiccated vegetation clawing at a sweltering sky. Worse yet, the world swarms with undead of all kinds. The cause of such a large scale infestation is unclear, nor is the reason they survive such close proximity to their star. Few scholars have the fortitude to try and uncover the secrets of this world, but there is a persistent trickle of adventuring types who try to brave the harsh surface for a chance at recovering lost wealth, artifacts and other valuables. Spelljamming crews often tell tales warning of getting too close to this planet sized tomb, cautioning that ghost ships still patrol its moribund orbit, flying ancient battle-flags long bleached bone-white.

Anahita: Earth type, Size D, 2 moons, Millions, Ancient Archive, Great Work

Once home to grand research campuses and the collected wisdom of the Sphere, it has long been said that the answer to any question worth asking could be found within the halls of Anahita. The population of this once grand world has dwindled in size and their ability to maintain the knowledge they have inherited. The centuries since the start of the Interregnum have seen the slow retreat of the population to the most important civic centers, leaving abandoned libraries and crumbling halls slowly being reclaimed by the wilds. The magocratic nobility have long since hoarded their fragmented knowledge, leaving critical Workings in disrepair. Some however, seek to reverse this trend, to reclaim lost knowledge and share it freely with the Sphere, and possibly beyond. The Prometheans, as they call themselves, are working to convert a captured asteroid into a spelljamming laboratory, archive and city all in one, some even dreaming of a fleet of such archives sailing the Phlogiston and bringing the light of knowledge to all.

Agathos: Earth type, Size F, 1 moon and a ring of asteroids, Hundreds of Millions, Restrictive Laws, Psionics/Magic Fear

Luddites but for magic. Powerful agrarian culture, breadbasket for the system and they know it.

For centuries the world of Agathos has been lush with the hard earned produce of the land. While very large for an earth class world, the world is not dense and lacks much in the way of tectonic or volcanic activity. Combined with the warm climate, the world is phenomenally agriculturally productive. Relatively few major population centers exist, typically built around a trade nexus, a culturally important site, or a major seat of the nobility. They serve as a major breadbasket for much of the Cervinus system and for the Sphere as a whole.

Cobano: Earth type, Size E, Asteroid belt, colder than normal, Hundreds of Millions, Tyranny, Starforged population

Cobano stands ringed by an asteroid belt, once rich with ores that fueled the expansion and development of the greatest works of the Threefold Empire. Many of the mines have long since been replaced by forges, testing grounds, shipyards, and orbital citadels built using similar techniques used to build traditional dwarven sky-holds. Modern Cobanan nobility holds sway over industrial and trade centers, guild and merchant house having merged with noble family structures over the centuries. The dense population relative to the other Cervinian worlds is in part due to the large population of Starforged automata that serve as the backbone of industrial labor. Strict management of their populations are maintained by the noble class, both to prevent overuse of the expensive materials and magics needed to forge individual units, and to prevent unrest from taking root.

Ilmarinen: Earth type, Size G, water ice ring, Hundreds of thousands, Gold Rush, Refugees

Settlements among the iceteroids, former spacefaring refugee culture formed during the Interregnum that has recently started to put down roots. Rich deposits of [SOMETHING] they have begun to exploit and ship out. Lots of potential for infighting and outsiders muscling in on their new territory.

Alaz, Fire type, Size G, belt, Vacuum (toxic air), none

Not a habitable body, this world is a swirling mix of toxic gases that often combust, putting off quite a bit of heat if one dares to come too close. With no appreciable moons, no easy to exploit resources, and with no land to settle, Alaz does not bring much traffic. The sole exception to this can be found in the lizardfolk of the Cervinus system, who use its tamer and more accessible orbit for their brood-barques. Such flotillas are heavily guarded, though the confluence of lizardfolk clans often leads to trade between the attendant clans and enterprising outsiders, as the heavy patrols serve to discourage otherwise enterprising pirates.

Nammu, Water type, Size C, asteroids in orbit, Millions, Societal Despair, Irradiated world

A small poisoned water world, this planet is home to a slowly dwindling population. It never quite recovered from the decline of the Threefold Empire. The cause of the poisoning of the seas in recent centuries is not certain, but is thought to be magical in nature. The declining population, combined with squabbling and petty wars between noble houses has made for a grim, dying world.

Volos: Earth type, Size F, Spherical, earthen rings, Several Million, Arcane Consulate, Growing Eidolon

Volos is a frozen super-earth world, massive, barren and cold. The world is valuable and settled not on the rocky surface, but in its orbit. The rings around it, likely the remains of a shattered moon, are host to multiple massive asteroids that border on dwarf planets at the largest. The greatest of these, Volos Prime, is host to an Arcane Consulate, and thus attracts much traffic and trade. It serves as a small but independent center of trade and power within the system, and the rings have grown to be populated with many small outposts and settlements that provide services to the consulate, from hollowed out farming or water harvesting asteroids, to mercenary star-forts offering patrol services, to the occasional dwarfhold offering to trade manufactured goods. Merchant convoys (and thus sky-pirates) are a common sight among the rings. Imported or farmed lumber and forged metals feed the shipyards of Volos Prime, making it quite easy, or at least reasonably affordable, to source common spelljammer designs.

Cardea, Air type, Size G, 4 moons Fewer than a million, Storm-Wracked, Floating Islands

Cardea is a distant sparsely populated world. A gas giant that sits quite far from the center of the system, it serves as a valuable stopping point for ships emerging from the Flow. The air is breathable, allowing for refreshing of their air envelopes. A handful of settlements exist on their storm-wracked islands, serving as rest stops and trade posts. Piracy is a concern, and the local militias are often in need of assistance in one form or another.

Chione: Water type, Size F, earthen rings between 1 and 2 million, Quarantined, Secret Masters

Officially not settled, Chione is technically a water world. However, far from the warmth of Cervinus the frozen crust of thick ice prevents easy settlement, though a handful are known to exist built into mountaintops. It is also known that there are a number of settlements that dot the asteroid belt, though no official census exists. It is suspected that these are havens for pirates, criminals and those that wish to disappear from the system at large. Far fetched and often whispered tales speak of some grand conspiracy that uses these supposed outposts to coordinate some task, though what that task may be varies with the teller and the strength of their drink.

4 notes

·

View notes

Text

Dehumidifier Supplier in India Key To Moisture-Free Industrial Environments

A reliable dehumidifier supplier in India plays a critical role in supporting various industries where moisture control is vital. From pharmaceuticals and food processing to electronics and data centers, maintaining optimal humidity levels ensures product quality, safety, and operational efficiency. As demand for advanced humidity control systems rises, several dehumidifier manufacturers in India are offering highly efficient, customizable solutions. This blog explores the importance, types, benefits, and market trends related to industrial dehumidifiers in the Indian landscape.

What Is a Dehumidifier?

A dehumidifier is a device designed to reduce and maintain the level of humidity in the air. It helps protect sensitive products and machinery from moisture-related damage. Industrial dehumidifier and commercial dehumidifiers are engineered for heavy-duty operations and can handle large volumes of air in warehouses, production floors, and laboratories.

Applications of Dehumidifiers Across Industries

Pharmaceutical Industry Precise humidity control is essential during the manufacturing and packaging of medicines. Dehumidifiers help in maintaining Good Manufacturing Practices (GMP) and avoid moisture-induced degradation.

Food & Beverage Processing In food storage and production units, moisture leads to spoilage and microbial growth. Dehumidifiers keep storage spaces dry and hygienic.

Electronics & Semiconductor Manufacturing Electronic components are highly sensitive to moisture. Controlled environments ensure better product life and safety.

Cold Storage & Warehouses Moisture condensation can affect stored goods and packaging. Dehumidifiers prevent condensation and protect the stored inventory.

Chemical Industry Many chemical compounds react with moisture. Dehumidifiers prevent unwanted reactions and ensure consistent chemical properties.

Data Centers & Server Rooms High humidity can cause equipment corrosion and system failure. Industrial-grade dehumidifiers help maintain optimal environmental conditions.

Types of Industrial Dehumidifiers

Refrigerant Dehumidifiers These units cool the air to condense and remove moisture. They are ideal for environments with high temperatures and moderate humidity.

Desiccant Dehumidifiers These use moisture-absorbing materials and are effective in low-temperature, low-humidity environments. They are widely used in pharmaceuticals and electronics.

Wall-Mounted Dehumidifiers These space-saving models are suitable for cleanrooms, labs, and compact workspaces.

Ducted Dehumidifiers Integrated with HVAC systems, ducted units are perfect for large industrial setups requiring central humidity control.

Portable Industrial Dehumidifiers These are movable units that offer flexibility in moisture control across multiple spaces.

Benefits of Using Industrial Dehumidifiers

Prevention of Mold & Bacterial Growth: Moisture breeds microbes. Dehumidifiers keep workspaces sterile and safe.

Increased Equipment Life: Corrosion due to humidity is reduced, increasing the lifespan of electronic and mechanical equipment.

Improved Product Quality: Sensitive goods like tablets, powders, chips, and circuits maintain their consistency.

Energy Efficiency: Advanced models consume less energy, reducing operational costs.

Regulatory Compliance: Industries meet international quality and safety standards, avoiding audit failures or product recalls.

Market Overview: Dehumidifier Demand in India

The Indian market for industrial dehumidifiers is expanding due to the rapid growth of climate-sensitive sectors. With the pharmaceutical and food industries focusing on global exports, maintaining humidity-controlled environments is now mandatory.

Key growth drivers include:

Expansion of industrial infrastructure

Growth in pharma and biotech manufacturing

Strict regulatory standards like GMP and ISO

Rise in data center installations

Increased awareness about indoor air quality

Role of Dehumidifier Manufacturers in India

Local dehumidifier manufacturers in India are offering high-performance, energy-efficient units tailored for domestic and export markets. They provide complete solutions—from site evaluation and system design to installation and maintenance.

These manufacturers offer:

Custom-built dehumidifiers suited to industry-specific needs

Scalable solutions for large and small facilities

In-house R&D for innovative design

Advanced control systems with remote monitoring

Compliance with global quality and safety norms

Several manufacturers also supply dehumidifiers to OEMs and HVAC integrators, making them a crucial link in India's industrial supply chain.

Choosing the Right Dehumidifier Supplier in India

Selecting a dependable dehumidifier supplier in India requires evaluating several critical factors:

Experience and Industry Knowledge: Suppliers should understand regulatory demands and technical specifications relevant to your industry.

Range of Products: Ensure the supplier offers various models for different humidity loads and space sizes.

Technical Support: Reliable after-sales service, AMC (Annual Maintenance Contract) options, and spare parts availability are essential.

Customization Capability: Look for suppliers who can tailor products for cleanrooms, warehouses, or high-risk areas.

Energy Efficiency: Choose dehumidifiers that offer the best performance with the lowest energy consumption.

Certifications: Products should comply with ISO, CE, or other relevant standards, depending on your operations.

Export Potential of Indian Dehumidifiers

With increasing demand in Southeast Asia, the Middle East, and Africa, Indian dehumidifier suppliers are gaining traction globally. The ability to deliver cost-effective, quality-assured solutions gives them a competitive edge in the international market.

Export-friendly features include:

Modular and compact designs

Easy installation and maintenance

Compatibility with global voltage/frequency standards

Digital humidity control and monitoring features

Future Outlook

The future for dehumidifier manufacturers in India looks promising. As industrial sectors continue to modernize, the requirement for moisture control systems will grow exponentially. Advancements like IoT-enabled dehumidifiers, AI-based humidity forecasting, and integration with building management systems (BMS) are set to redefine the industry.

Focus on sustainability and energy conservation will also drive innovation in refrigerant and desiccant technologies. With increasing emphasis on health, safety, and compliance, dehumidifiers will become an indispensable part of every regulated industry.

Conclusion

Moisture control is no longer optional—it’s essential for quality-driven industries. A trusted dehumidifier supplier in India provides more than just equipment—they offer assurance of performance, compliance, and reliability. Backed by strong local manufacturing capabilities, dehumidifier manufacturers in India are setting new benchmarks in product innovation, cost-efficiency, and global competitiveness. As industrial demand rises, these solutions will continue to support India's journey toward high-precision, climate-controlled production environments.

#dehumidifier manufacturers in india#dehumidifier supplier in india#industrial dehumidifier#top hvac companies in india#modular ot#hvac manufacturers in india

0 notes

Text

Laboratory Oven: Types, Uses & How to Choose the Right One for Your Lab

A laboratory oven is a critical piece of equipment used in scientific, medical, pharmaceutical, and industrial laboratories for a wide range of thermal processing tasks. From sterilization and drying to baking and heat treatment, lab ovens offer precise temperature control and uniform heat distribution.

This article explains what a laboratory oven is, the different types available, common applications, and what to consider when choosing the right oven for your lab.

What Is a Laboratory Oven?

A Laboratory Oven is a temperature-controlled device used to heat and maintain a consistent temperature for samples, instruments, or materials. These ovens typically operate in a temperature range of ambient +5°C to 300°C or more, depending on the model.

Laboratory ovens are designed for:

Drying glassware or samples

Curing or baking materials

Dehydration or desiccation

Sterilization

Heat treatment of chemicals or metals

Common Types of Laboratory Ovens

1. Gravity Convection Ovens

Uses natural air circulation

Cost-effective and ideal for gentle drying

Lower airflow, longer heating times

2. Forced Air Convection Ovens

Uses a fan to distribute heat evenly

Faster temperature recovery and uniformity

Ideal for applications needing consistent heating

3. Vacuum Ovens

Operates under reduced pressure

Prevents oxidation or contamination

Suitable for delicate samples or heat-sensitive materials

4. Cleanroom Ovens

Designed for use in sterile environments

HEPA filtration systems to prevent contamination

Common in pharmaceutical and semiconductor labs

Applications of Laboratory Ovens

Laboratory ovens are used across various industries, including:

Biotechnology & Life Sciences: Drying biological samples and sterilizing labware

Pharmaceuticals: Curing and stability testing

Research & Academia: Controlled sample heating in experiments

Industrial Labs: Heat-treating components or materials

Electronics: Drying printed circuit boards (PCBs) or coatings

Key Features to Consider When Choosing a Laboratory Oven

✅ Temperature Range & Uniformity

Make sure the oven meets your process requirements and maintains consistent temperatures throughout the chamber.

✅ Chamber Size & Volume

Select a size based on your lab space and the size/number of items you’ll be heating.

✅ Airflow Type

Decide between gravity or forced air, depending on how fast and Vacuum Oven uniform heating you need.

✅ Safety Features

Look for over-temperature protection, alarms, and auto shut-off functions.

✅ Compliance & Certification

Ensure the oven complies with ISO, ASTM, or CE standards if required for regulated environments.

FAQs About Laboratory Ovens

1. What is the difference between a lab oven and a regular oven?

A laboratory oven offers precise temperature control, uniformity, and safety features designed for scientific applications—unlike household ovens that are less accurate and not suitable for research use.

2. How do I clean and maintain a laboratory oven?

Always unplug before cleaning

Use non-corrosive cleaners

Clean interior surfaces and fans regularly

Schedule professional calibration and maintenance annually

3. Can laboratory ovens be used for sterilization?

Yes, particularly forced-air and vacuum ovens. They can effectively sterilize glassware and instruments when operated at high temperatures for extended periods.

4. What temperature range is typical for a laboratory oven?

Most lab ovens range from ambient +5°C to 300°C, although some high-performance models can go up to 500°C or more.

5. Are vacuum ovens better for all samples?

Not necessarily. Vacuum ovens are ideal for heat-sensitive or oxidation-prone materials, but standard convection ovens are sufficient for general drying and sterilization.

Conclusion

A laboratory oven is an essential tool in any research, quality control, or industrial lab. Choosing the right model depends on your specific application, space, and temperature requirements. Whether you need simple drying or advanced heat treatment under vacuum, there’s a lab oven to match your needs.

For the best performance, always buy from a reputable supplier and ensure your oven is maintained and calibrated regularly. The right lab oven will improve efficiency, accuracy, and safety across all your thermal processing tasks.

1 note

·

View note

Text

High-Performance Silica Gel for Advanced Gas Dehydration Applications

Silica Gel Desiccants, a leading provider of industrial chemical solutions, is proud to announce the launch of its high-performance silica gel for gas dehydration, designed to meet the critical needs of industries requiring clean, dry, and contaminant-free gas streams.

Gas purification is essential in a wide range of sectors, including petrochemical, natural gas processing, pharmaceuticals, and electronics manufacturing. The newly introduced silica gel product — available in both silica gel orange beads and silica gel blue beads — offers exceptional adsorption capacity, thermal stability, and mechanical strength. This makes it ideal for removing moisture, hydrocarbons, and other impurities from gas mixtures.

Our silica gel is engineered to deliver superior drying and purification performance under the most demanding conditions. Whether you’re using silica gel blue crystals in laboratory applications or orange silica gel beads in large-scale industrial processes, the product plays a crucial role in ensuring the efficiency, safety, and quality of your gas operations.

Why Choose Silica Gel Desiccant for Gas Purification?

Silica Gel Desiccant stands out as a premier choice for gas purification needs due to its commitment to quality and safety:

High Adsorption Capacity: Capable of adsorbing up to 40% of its weight in moisture, ensuring efficient drying processes.

Visual Moisture Indicators: Available in both silica gel blue beads and orange silica gel beads, these desiccants offer a color-changing feature that allows for easy moisture level monitoring, minimizing downtime and reducing maintenance costs.

Environmental Compliance: The use of non-toxic indicators like methyl violet in orange silica gel beads aligns with global safety standards, making it suitable for sensitive applications.

Versatility: Offered in a variety of bead sizes, including silica gel blue crystals for specialized needs, the product range can be tailored to meet specific industry requirements, ensuring optimal performance.

Silica Gel Desiccant’s silica gel is available in a variety of bead and granular forms, including both orange and blue silica gels. It can be customized to meet specific customer requirements. Technical support and bulk delivery options are also available.

0 notes

Text

Sols 4532-4533: Polygon Heaven

Mars Science Laboratory Mission Team Members May 08, 2025 Written by Catherine O’Connell-Cooper, Planetary Geologist at University of New Brunswick Earth planning date: Monday, May 5, 2025 Our 29-meter weekend drive (about 95 feet) was successful, and we are still in the band of polygon-rich bedrock. The origin of these cracks is not clear — could they have formed as desiccation cracks as Mars…

0 notes

Text

Auto Dry Cabinets in India - Protect Your Sensitive Equipment with ASCOMP INC.

In industries where moisture control is critical, auto dry cabinets in India have become an essential investment. At ASCOMP INC., we provide high-performance auto dry cabinets designed to safeguard sensitive electronic components, laboratory equipment, and precision instruments from humidity damage.

Why Choose ASCOMP INC.’s Auto Dry Cabinets in India?

Our auto dry cabinets in India offer: ✔ Advanced Humidity Control – Maintains optimal RH levels (1-60%) ✔ Energy-Efficient Operation – Low power consumption with smart drying technology ✔ Durable Construction – Anti-corrosive powder-coated steel ✔ Customizable Storage – Adjustable shelves for flexible organization ✔ Real-Time Monitoring – Digital display with humidity and temperature readings

Applications of Auto Dry Cabinets

ASCOMP INC.’s auto dry cabinets in India are ideal for:

Electronics Manufacturing – Protects PCBs, semiconductors, and SMD components

Pharmaceutical Industry – Stores moisture-sensitive drugs and chemicals

Research Laboratories – Preserves precision instruments and optical devices

Defense & Aerospace – Ensures reliability of critical electronic systems

Museums & Archives – Protects valuable documents and artifacts

Key Features of ASCOMP INC. Auto Dry Cabinets

✅ Automatic Humidity Regulation – No manual intervention needed ✅ Silent Operation – Perfect for lab and industrial environments ✅ Secure Locking System – Prevents unauthorized access ✅ Low Maintenance – Long-lasting desiccant-free technology ✅ Multiple Size Options – From compact 30L to industrial 500L+ capacities

Technical Specifications

Humidity Range: 1% to 60% RH (adjustable)

Temperature Range: Ambient to 60°C (optional heating models available)

Power Supply: 220V AC, 50Hz

Recovery Time: <30 minutes after door opening

Safety Features: Overheating protection, alarm system

Why ASCOMP INC. Leads the Market

As pioneers in humidity control solutions, our auto dry cabinets in India stand out because:

Made with premium materials for long-term reliability

Backed by 2-year warranty and pan-India service support

Custom configurations available for specialized needs

Competitive pricing without compromising quality

Industries We Serve

Our auto dry cabinets in India are trusted by: 🔹 Electronics manufacturers 🔹 Pharmaceutical companies 🔹 Research institutions 🔹 Defense organizations 🔹 Telecommunication firms

Upgrade to ASCOMP INC. Auto Dry Cabinets Today!

Protect your valuable equipment from humidity damage with India's most reliable auto dry cabinets. Visit ASCOMPINC.COM to explore our product range or request a quote.

#ASCOMPINC#AutoDryCabinet#HumidityControl#ESDProtection#ElectronicsManufacturing#LabEquipment#PrecisionStorage#MadeInIndia#IndustrialSolutions#MoistureProtection

0 notes

Text

Understanding Key Components of Industrial Air Systems

Industrial air systems play a vital role in a wide range of industries. Whether in manufacturing, pharmaceuticals, food processing, or another field, these systems provide the necessary air supply for various processes while maintaining efficiency and safety. If you're someone who works with or manages industrial operations, understanding the key components of air systems is necessary to ensure optimal performance and reduce downtime within your facility. So, in this article, let's take a closer look at all the fundamental components of industrial air systems.

Air Compressors

Air compressors are the heart of the industrial air systems. They convert mechanical energy into compressed air, which is then used to power tools, machines, and other equipment. There are a variety of air compressors, such as rotary screws, centrifugal compressors, reciprocating, etc—all with their own benefits and applications. Air compressors also differ in size, so choose according to the air system's needs. An extensive system may require a vast compressor, while smaller systems may operate efficiently with compact or portable units designed for lower air demand.

Compressed Air Filters

A compressed air filter plays a crucial role in ensuring the air is clean for industrial processes. Impurities like dust, oil, water, and other particles reside in compressed air and affect equipment performance. A compressed air filter removes those impurities by using a combination of different mechanisms. These filters come in different types, including absorber, coalescing, and absorber filters. Particulate filters trap solid particles, while coalescing removes water and oil from the air. On the other hand, absorber filters remove traces of oil vapour and other contaminants affecting air quality.

Sterile Air Filters

If you're aware of the food processing, pharmaceuticals, and healthcare industries, you know just how critical air quality is. In these sectors, even small contaminants in compressed air can have serious implications, from affecting products to compromising patients' safety. Therefore, to ensure that the air is free of these contaminants, sterile filters are used to remove particles and harmful microorganisms, leaving clean and safe air. Now, let's understand how these filters serve different roles in different industries.

In food processing, sterile air filters are used to maintain the safety and hygiene of food products. The filters prevent airborne contaminants from entering processing and packaging areas.

In the pharmaceutical industry, contaminants can affect the production of medications, violating stringent regCompressed Air Filters, Sterile Air Filters, Nitrogen Gas Generatorulatory standards. Thus, sterile filters are used to maintain the quality and purity of all the medicines being manufactured.

In laboratories and medical facilities, sterile filters ensure that the air used in sensitive environments is free from harmful contaminants and microorganisms.

Air Dryers

Compressed air can be cleaned using filters, but what about its moisture? You may not know, but excessive moisture in compressed air can cause rust, corrosion, and contamination of machinery and products. This can also impact the quality of the air system, leading to increased energy consumption and increased energy failures. That's where air dryers offer a game-changing solution. These dryers are used to remove moisture from compressed air. Air dryers come in various types, such as refrigerated, membrane, and desiccant. Refrigerated dryers cool the air and cause the moisture to condense and separate from the air, while desiccant dryers absorb moisture using materials. On the other hand, membrane dryers use a semi-permeable membrane to allow water vapour to pass through, effectively removing moisture from the air.

When choosing the right air dryer, you need to consider the required level of dryness and your application needs.

Nitrogen Gas Generators

Some industrial applications require nitrogen gas for processes like packaging, metal fabrication, and chemical production. As nitrogen gas is inert, it does not react with other substances, making it ideal for preventing contamination or oxidation. A nitrogen gas generator is one of the key components of an air system that produces nitrogen on-site. These systems separate nitrogen from the air using either a membrane or PSA (Pressure Swing Adsorption) technology. The system filters out oxygen and other gases and provides a reliable source of nitrogen. Additionally, it eliminates the need for expensive bottled nitrogen.

In food processing industries, nitrogen is commonly used to displace oxygen in packaging materials. This helps preserve the freshness and shelf life of the food product. In electronics manufacturing industries, nitrogen gas generators are used to maintain a controlled nitrogen environment for sensitive processes.

Pressure Regulators

After compressing, filtering, and drying the air, it is delivered to the various parts of the system at the correct pressure. Pressure regulators maintain the desired pressure levels within the air system to prevent over-pressurization, which could damage equipment or cause safety issues.

Wrapping Up

I hope you're now familiar with the above key components of the air system. Each component–from air compressors to filters, dryers, and pressure regulators- is vital in delivering clean, dry, and safe air for industrial processes. By understanding these key components and their unique functions, industries can optimize their operations, reduce energy consumption, and maintain high levels of product safety and quality Compressed Air Filters

1 note

·

View note

Text

The Best Ways to Protect Fragile Equipment During Relocation

Relocating fragile equipment, whether it’s industrial machinery, laboratory instruments, or delicate electronic systems, requires careful planning and execution. Mishandling during transport can result in costly damages, downtime, and even safety hazards. That’s why businesses trust professionals like Eagle Equipment Moving & Rigging, a leading heavy equipment moving company, to ensure secure and efficient transportation.

In this guide, we’ll explore the best ways to protect fragile equipment during relocation, covering essential preparation steps, packing techniques, transportation considerations, and unloading best practices.

Understanding the Risks of Moving Fragile Equipment

Fragile equipment is particularly susceptible to:

Vibrations and shocks that can damage internal components.

Temperature fluctuations and humidity that can lead to malfunctions.

Improper handling that results in cracks, dents, or misalignment.

Unsecured loads that shift during transport, causing structural damage.

To avoid these risks, businesses should follow a strategic approach when moving delicate machinery and equipment.

Step-by-Step Guide to Protecting Fragile Equipment

1. Conduct a Pre-Move Assessment

Before relocating any fragile equipment, perform a thorough assessment to determine:

Equipment size and weight to choose the right transportation method.

Specific vulnerabilities such as sensitive wiring, glass panels, or precision parts.

Disassembly requirements to ensure safer handling.

Environmental factors like humidity control needs or shock sensitivity.

A professional rigging company near me will conduct a detailed evaluation and create a customized moving plan to safeguard fragile machinery.

2. Use the Right Packing Materials

Proper packing is crucial to prevent damage. Some of the best packing materials include:

Shock-absorbing foam padding to reduce vibrations.

Anti-static wraps for electronic equipment.

Heavy-duty crates and custom containers for maximum protection.

Moisture barriers and desiccants to prevent condensation damage.

Palletizing and securing equipment with straps to prevent shifting.

Using high-quality materials ensures equipment remains intact throughout the relocation process.

3. Disassemble When Necessary

Some fragile equipment can be transported more safely if it is partially or fully disassembled. This includes:

Removing detachable parts such as control panels, screens, and fragile attachments.

Labeling and storing screws, bolts, and connectors to simplify reassembly.

Packaging delicate components separately for added protection.

Professional movers from Eagle Equipment Moving & Rigging can safely disassemble and reassemble machinery to minimize the risk of damage.

4. Choose the Right Transportation Method

Selecting the correct transport vehicle and method is key to ensuring a smooth relocation. Options include:

Air-ride suspension trucks to reduce shocks and vibrations.

Climate-controlled trailers for temperature-sensitive equipment.

Flatbed trailers with custom enclosures for oversized delicate machinery.

Lowboy trailers for heavy yet fragile equipment that requires extra stability.

A trusted heavy equipment moving company will determine the best transportation option based on the type and sensitivity of the equipment.

5. Secure Equipment Properly for Transport

Ensuring the load is stable and secure prevents shifting and damage. Best practices include:

Using heavy-duty ratchet straps and braces to immobilize the load.

Placing cushioning materials between stacked equipment to avoid contact damage.

Ensuring proper weight distribution to prevent tilting or tipping.

Applying tilt and shock indicators to monitor handling conditions.

6. Monitor Environmental Conditions

Many fragile machines are sensitive to temperature, humidity, and dust. To mitigate these risks:

Use dehumidifiers or silica gel packs to control moisture inside packaging.

Cover electronics with anti-static shielding to prevent electrostatic discharge.

Transport in climate-controlled trucks if extreme temperatures could cause damage.

Minimize exposure to outdoor elements during loading and unloading.

A rigging company near me with experience in delicate equipment moving will have the tools and knowledge to maintain optimal transport conditions.

7. Hire Trained Professionals for Loading and Unloading

The most critical phase of relocation is the handling of fragile equipment during loading and unloading. Experienced movers follow best practices such as:

Using forklifts and cranes with precision control to lift delicate loads.

Operating at slow, controlled speeds to avoid sudden jolts.

Implementing team-based lifting to evenly distribute weight and minimize strain.

Following detailed unloading procedures to prevent impacts or mishandling.

By working with professionals from Eagle Equipment Moving & Rigging, businesses can ensure their equipment is handled with expert care.

8. Conduct a Post-Move Inspection and Testing

After relocation, inspect and test equipment before putting it back into operation. Steps include:

Checking for visible signs of damage such as cracks, loose connections, or misalignment.

Reassembling and calibrating machinery as per manufacturer guidelines.

Running diagnostic tests to verify proper function before full use.

Documenting any irregularities for further assessment.

Why Hire a Professional Heavy Equipment Moving Company?

Choosing a reliable heavy equipment moving company is the best way to ensure a successful relocation. Key benefits of hiring experts include:

Specialized experience in handling fragile and sensitive equipment.

Access to high-quality packaging and rigging solutions.

Compliance with safety regulations to avoid costly penalties.

Efficient and timely execution to minimize downtime.

Full insurance coverage for added peace of mind.

If you’re searching for equipment hauling near me, partnering with Eagle Equipment Moving & Rigging ensures your fragile equipment is relocated with the highest level of care and precision.

Conclusion

Protecting fragile equipment during relocation requires careful planning, expert handling, and the right transportation strategies. Businesses can prevent damage and minimize risks by following best practices such as using specialized packing materials, securing loads properly, and hiring professionals for transport and unloading.

With Eagle Equipment Moving & Rigging, companies can rely on experienced professionals who understand the complexities of moving delicate machinery. Whether you need a trusted rigging company near me, a heavy equipment moving company, or equipment hauling near me, choosing the right experts will ensure a smooth and damage-free relocation process.

Eagle Equipment Moving & Rigging 69 Pavilions Dr Suite 1, Manchester, CT 06042, United States 1-860-750-9594 https://eaglerigging.com/heavyequipmentmoving-manchesterct/

0 notes

Text

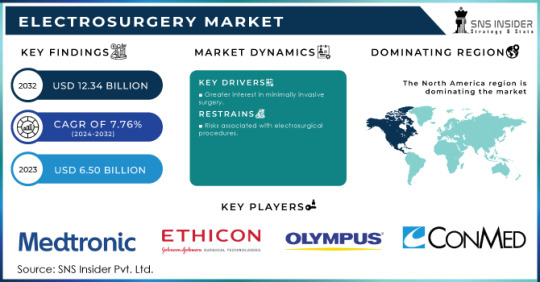

Electrosurgery Market: Market Forecast and Industry Outlook 2024-2032

The Electrosurgery Market Size was valued at USD 6.50 billion in 2023 and is expected to reach USD 12.34 billion by 2032, growing at a CAGR of 7.76% over the forecast period 2024-2032.

Market Overview

Electrosurgery, a technique that utilizes high-frequency electrical currents to cut, coagulate, desiccate, or fulgurate tissue, has become a vital component in modern surgical practices. Its precision, minimal invasiveness, and efficiency have fueled its adoption across a wide range of medical specialties, driving significant market expansion globally.

Get Free Sample Report @ https://www.snsinsider.com/sample-request/3394

Regional Analysis

North America: Leads the global market, supported by advanced healthcare systems, high adoption of innovative surgical technologies, and a large volume of surgical procedures.

Europe: Maintains a strong market share, driven by well-established medical device companies and increasing preference for minimally invasive surgeries.

Asia-Pacific: Expected to experience the fastest growth rate, owing to rising healthcare investments, increasing patient awareness, and a growing geriatric population.

Rest of the World: Also witnessing steady growth due to improvements in healthcare infrastructure and expanding access to advanced surgical treatments.

Market Segmentation

By Product:

Electrosurgical Instruments

Electrosurgical Generators

Electrosurgical Accessories

Smoke Evacuation Systems

By Surgery:

General Surgery

Obstetric/Gynecological Surgery

Orthopedic Surgery

Cardiovascular Surgery

Oncological Surgery

Cosmetic Surgery

Urological Surgery

Neurosurgery

Other Surgeries

By End User:

Hospitals, Clinics, and Ablation Centers

Ambulatory Surgical Centers

Research Laboratories and Academic Institutes

Key Players

The major players are Medtronic, Ethicon US, LLC., Olympus Corporation, CONMED Corporation, Erbe Elektromedizin GmbH, Bovie Medical Corporation, Braun Melsungen AG, BOWA-electronic GmbH & Co. KG, Kirwan Surgical Products, LLC., Parkell, Inc, and others.

Key Market Drivers

Rising demand for minimally invasive surgical procedures

Continuous technological advancements in electrosurgical devices

Increasing prevalence of chronic conditions requiring surgery

Growing elderly population worldwide

Future Scope

The electrosurgery market is set to witness substantial growth over the coming years, propelled by ongoing innovations in surgical technologies and the expanding demand for less invasive, more precise surgical techniques. Emerging economies, particularly in Asia-Pacific and Latin America, are expected to offer lucrative opportunities due to improving healthcare systems and rising healthcare spending. Furthermore, integration of electrosurgical tools with robotic and AI-assisted surgery platforms will likely redefine patient care standards and surgical precision in the future.

Conclusion

Electrosurgery has firmly established its role in enhancing surgical outcomes through its efficiency and precision. With the momentum of technological progress and increasing demand for safer, minimally invasive procedures, the electrosurgery market is anticipated to achieve remarkable growth, delivering enhanced benefits to healthcare providers and patients alike.

Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Other Related Reports:

Fertility Services Market

Medical Power Supply Market

Post Traumatic Stress Disorder Treatment Market

MRI Guided Neurosurgical Ablation Market

#Electrosurgery Market#Electrosurgery Market Share#Electrosurgery Market Trends#Electrosurgery Market Size#Electrosurgery Market Growth

0 notes

Text

Choosing the Right Laboratory Glassware Exporter: Factors to Consider

Selecting the best laboratory glassware exporters is crucial for ensuring high-quality, durable, and precise glassware for scientific applications. Whether you need beakers, test tubes, flasks, or specialized lab glassware, choosing a reliable exporter guarantees accuracy, safety, and compliance with international standards. Here are the key factors to consider before making your decision:

1. Quality Standards & Certifications

High-quality laboratory glassware must meet international safety and performance standards. Ensure the exporter follows ISO, ASTM, CE, or NABL certifications to guarantee accuracy and durability. Look for borosilicate glass, which offers high resistance to heat and chemicals.

2. Product Range & Customization

A good laboratory glassware exporter should offer a diverse range of products, including:

Beakers, flasks, and measuring cylinders

Test tubes and pipettes

Condensers and burettes

Glass funnels and desiccators

Additionally, check if they provide customized glassware based on specific laboratory needs.

3. Reputation and Industry Experience

Choosing experienced laboratory glassware exporters ensures quality assurance and reliable supply chains. Check for client testimonials, industry reputation, and years of experience to verify their credibility.

4. Packaging & Safe Shipping

Laboratory glassware is fragile and requires secure packaging for international transport. Ensure the exporter follows protective packaging protocols like shock-resistant wrapping and sturdy boxes to prevent damage during shipping.

5. Pricing & Bulk Order Discounts

Compare pricing from different laboratory glassware exporters to get competitive rates without compromising on quality. Many exporters offer bulk order discounts and flexible payment options for large shipments.

6. Timely Delivery & Global Reach

Reliable exporters should have a strong logistics network to ensure on-time deliveries across different countries. Check their shipping policies, lead times, and distribution channels before placing an order.

7. Customer Support & After-Sales Services

A trustworthy laboratory glassware exporter should provide excellent customer support, including: ✅ Quick response to inquiries ✅ Assistance with product selection ✅ Order tracking and issue resolution

Conclusion

Selecting the right laboratory glassware exporters requires evaluating product quality, certifications, pricing, delivery timelines, and customer service. By choosing a reputable exporter, you can ensure precision, durability, and efficiency in laboratory operations.

Looking for high-quality laboratory glassware exporters? Partner with a trusted supplier today!For more information visit us: https://www.shivsons.com/exploring-the-world-of-glassware-exporters/

0 notes

Text

What Are the Most Common Mistakes in Biology Laboratory Equipment Maintenance?

Biology Laboratory Equipment proper servicing ensures accurate results and safety in a laboratory environment. Many biology laboratories, ranging from research to education, use advanced tools in performing their experiments. Using a Desiccator, Dissecting Microscope, Scalpel Blade, Dropping Bottle, and Digital Flame Photometer, various biological activities can be carried out in the laboratories. These instruments are important but when not properly maintained, they tend to fail very often and the data collected is worthless. In this blog, we will discuss five common maintenance issues, how to avoid them, and why you should work with credible biology laboratory equipment manufacturers and suppliers for impeccable quality.

5 Common Maintenance Mistakes and How to Prevent Them

Ignoring Regular Upkeep

With time, dust and biological residues can accumulate on the surfaces of equipment, especially on items like photometers and microscopes. Utilization of lint-free fabrics and suitable cleaning agents on a regular basis can avert this damage. In the case of the Dissecting Microscope, lenses must be inserted in containers free of dust and other contaminants to maintain their good optical quality.

Using Inappropriate Cleaning Agents

Some laboratory workers tend to use corrosive cleaning agents that may deteriorate delicate equipment such as Dropping Bottles over a long period of use. Use only the specified cleaning agents and consult user manuals specific to each equipment for recommended cleaning methods so that equipment useful life is extended.

Uncalibrated Equipment

Sometimes researchers forget to calibrate their instruments and as a result, they are unable to obtain the desired measurements. It is recommended to reinforce the procedure for regular calibration of devices as prescribed by Biology Laboratory Equipment manufacturers and suppliers in India. This is especially crucial in research laboratories where the accuracy of results is the key factor.

Dismissing Storage Instructions

Numerous laboratories fail to store equipment correctly which results in damage to the instrument. For instance, a desiccator should be kept in a cool and dry environment in order to prevent moisture build-up, while fragile items such as scalpel blades should be placed safely in sterile containers.

Neglecting Maintenance Services

With the passage of time, there could be instances of some hidden wear and tear which may not be apparent. A regular inspection enables attention to reasons such as loose screws, broken seals, or worn out items. Periodic maintenance checks ensure that any harm that can lead to bigger complications and risks is dealt with at the nascent stage.

Essential Biology Laboratory Equipment and Their Maintenance

Dissecting Microscope

A vital instrument in biological dissections and viewing of samples, a dissecting microscope is one of the pieces of equipment that has to be properly used and must be calibrated all the time.

Scalpel Blade

Employed to make cuts during dissection cutting, scalpel blades are handled and kept in a safe manner in sterilized storage and should also be changed often to ensure sharpness.

Desiccator

The desiccator is crucial in preventing contamination of biological samples that are prone to moisture. Additionally, regular upkeep and maintenance routines alongside correct storing are the most effective means of preserving the tool.

According to Wikipedia, Cobalt chloride paper and other moisture-sensitive materials can be preserved for later use by using desiccators, which are sealable containers filled with desiccants. Desiccators are frequently used to shield hygroscopic or water-reactive compounds from humidity.

Dropping Bottle

An attachment for dispensing small amounts of liquid, and dropping bottles should be disinfected and examined for cracks to avoid the risk of contamination and leakage.

Digital Flame Photometer

This device quantitatively determines the concentration of certain elements in biological specimens. Regular and proper maintenance of this device is highly critical, as it involves calibration and cleaning after every few usages.

Why Choose School Educational Instruments?

As a reputable Biology Laboratory Equipment manufacturer and supplier in India, School Educational Instruments offers an impressive range of high-grade materials and equipment that have been carefully designed to provide years of dependable service. School Educational Instruments emphasizes customer satisfaction by providing effective assistance and proper guidance regarding the use and maintenance of the equipment so that your laboratory is efficient and safe.

Conclusion

It is crucial to take good care of all Biology Laboratory Equipment to make sure that it is accurate, safe, and can last long in any biological laboratory. By avoiding these common maintenance mistakes, laboratory staff can prevent equipment malfunctions and unnecessary breakage but most importantly improve the quality of their experiments. School Educational Instruments is a trusted Biology Laboratory Equipment manufacturer and supplier in India. With proper maintenance, your laboratory can maintain a good standard which helps researchers and students in carrying out their scientific endeavors.

#biology laboratory equipment manufacturers and suppliers#biology laboratory equipment manufacturer#biology laboratory equipment manufacturers and suppliers in india

0 notes

Text

What Are the Benefits of Working with a Professional Laboratory Glassware Manufacturer in Kenya

When setting up a laboratory or upgrading equipment, choosing the right laboratory glassware manufacturer is vital for ensuring accuracy, safety, and efficiency in various scientific procedures. Laboratory glassware includes simple equipment such as beakers, and test tubes to more advanced equipment such as burettes and condensers which are necessary for every single activity within the field of science. Engaging a professional laboratory glassware manufacturer in Kenya ensures quality, perfect, and lasting products within international standards. They enable laboratories, universities, research institutions, and even health facilities to have access to innovative inventions plus tailor-made alternatives concerning laboratory glassware. In this blog, we will discuss the benefits of working with a professional laboratory glassware manufacturer in Kenya.

Benefits Of Choosing A Professional Laboratory Glassware Manufacturer In Kenya

Quality Control And Safety Guarantee

A notable advantage of dealing with a Laboratory glassware manufacturer is the ability to guarantee products of a very high quality, which also complies with international safety standards. Laboratory work is highly demanding fueled by the level of accuracy needed, and inaccuracy in laboratory glassware quality can lead to errors in the experiments or lead to hazardous situations. High-grade materials such as borosilicate glass, which is known for its properties, are used by such professional manufacturers.

Manufacturers conduct regular quality check measures on the laboratory glassware so that they are defect-free and are made to withstand revolutionary operational activities that are witnessed at the laboratories. Such levels of assurance decrease the chance of breakage or malfunction during vicious experiments, in turn, safeguarding laboratory personnel.

Personalization for Certain Needs

Depending on the discipline, research, or production, laboratories can have specific needs as well. An expert in Laboratory glassware manufacturing in Kenya can work on solutions that meet particular demands. Whether it is volumetric flasks, custom-made condensers, or test tubes of any shape, requiring a certain degree of skill, advanced manufacturers can develop such custom laboratory glassware for you.

Customization in this degree of therapeutic product is very important for laboratories with specialized research since the general laboratory products do not always translate to the required outcome. Custom laboratory glassware comes in handy as it improves the quality and performance of the experiments, thus increasing the accuracy of the outcomes.

Endurance and Long-Term Use of The Equipment

In the quest for laboratory glassware, it will be prudent to take into consideration the aspect concerning the durability of the glass as replacing them often may be expensive and interfere with operations. Professional manufacturers use the best quality glass products such as borosilicate or quartz with the intent to withstand scientific testing for longer periods.

These materials are able to withstand high temperatures, chemicals, and mechanical stress and hence can be used multiple times without failure. This, in turn, helps to minimize costs owing to less frequent replacement of equipment and minimizes the risk of experiment failure arising from the use of damaged equipment.

Diverse Range of Products for Various Uses

A professional Laboratory glassware manufacturer is supposed to present most of the lab equipment and its accessories which can be used in different laboratory applications. Such elementary items would be considered as beakers or Erlenmeyer flasks, while more elaborate instruments would include distillation apparatus, burettes, or desiccators. Having such a variety of glassware ensures that your laboratory space is less likely to lack sufficient Laboratory glassware for several experiments and processes.

Additionally, manufacturers know that there is always a demand for better glassware, usually in different sizes and shapes, thus they stock flexible Laboratory glassware resulting in every task being done with the right equipment. This is more so due to the fact that laboratories with multiple disciplines have different requirements in terms of equipment used in different research.

Key Laboratory Glassware

Beakers

Beakers are round and shaped vessels that mainly facilitate holding, mixing, stirring, or even heating of liquids. They come in different shapes and sizes and are mostly made from borosilicate to enable heat and chemical resistance.

Test Tubes

A test tube is a thin glass or plastic cylindrical container that is used for mixing as well as holding small amounts of liquids which is then heated. These test tubes are essential for chemical reactions, biological assays as well as other tests.

Burettes

An instrument utilized to measure and dispense known volumes of a liquid within a specific range, usually in titration processes. Burettes also contain graduated scales which enable good reading of the volumes of the liquids dispensed.

Conical Flasks (Erlenmeyer Flasks)

Conical Flasks are one of the fundamental glass containers in a chemistry laboratory and are very useful in mixing liquid or controlling the volatile gases released because the neck is narrow.

Condensers

Condensers in chemistry are used during separation processes involving distillation and serve the purpose of cooling the vapors to liquid conversion, therefore having great importance in chemical separation and purification processes.

After Sales Service and Technical Help

The benefit and wisdom of dealing with a professional Laboratory glassware manufacturer is the availability of after-sale service and technical support help. An excellent number of laboratories will need assistance on how to use, clean, and even maintain their glass apparatus for better utility. Professional manufacturers provide manufacturability training, manuals, and other support services to assist the lab in the efficient, effective, and safe use and bearing of the equipment.

Furthermore, in case of downtime due to glass wear and tear, manufacturers are available to offer new, repaired glassware or troubleshoot the defects. This kind of support prevents laboratories from losing production time as a result of having defective or broken instruments.

Why Should You Choose LSS Kenya?

LSS Kenya is a leading Laboratory glassware manufacturer in Kenya, which enables you to acquire high-quality, durable, and tailor-made Laboratory glassware for laboratory settings. The institution fulfills the international quality standards that make LSS Kenya products safe, dependable, and durable. LSS Kenya has become a household brand and is well-stocked with all laboratory glassware such as beakers, flasks, burettes, and others required for beaker science and many more. In addition, LSS Kenya Offers Excellent after-sales services to ensure that your laboratory is properly outfitted and your personnel adequately trained to use and service the fittings. For such reasons, they make sure by associating with LSS Kenya all laboratory glassware needed in the laboratory for performing the scientific processes is available.

#laboratory glassware manufacturer in Kenya#laboratory glassware manufacturer#laboratory glassware manufacturer Kenya

0 notes

Text

A New Dawn for Humanity: Cliffy, Chugalugging, and Pyridoxins in a World on the Brink

In the year 2137, as the Earth’s biosphere groans under the crushing weight of anthropogenic folly, a revolutionary elixir of hope has emerged: the Pyridox™ Complex, an audacious synthesis of cliffy ingenuity, chugalugging efficiency, and cutting-edge pyridoxins—those miraculous derivatives of Vitamin B6 that might yet redeem humanity’s ecological debts. Designed to bolster human resilience in a world ravaged by ecological upheaval, Pyridox™ fuses bioengineered nutrients with nanotechnological enhancements, transforming mere sustenance into a transformative act of survival. As sea levels encroach on the metropolises of yesteryear and the desiccated husks of forests crumble to ash, the promise of Pyridox™ is nothing short of epochal: a lifeline tethered to the dwindling vestiges of a once-prosperous planet.

At its core, the Pyridox™ Complex thrives on the principle of chugalugging—a rapid, almost ceremonial consumption of life-sustaining compounds that optimizes bioavailability in an increasingly inhospitable climate. Delivered in a sleek, recyclable canister derived from algae-based bioplastics, Pyridox™ requires only a single “chug” to deliver a cascade of regenerative energy, cellular repair mechanisms, and an uncanny resistance to environmental toxins. But the real innovation lies in its "cliffy" factor—a nod to its development in the vertiginous laboratories clinging to the sheer cliffs of New Patagonia, where researchers extracted inspiration from extremophilic organisms that thrive against insurmountable odds. Pyridox™ does not merely nourish; it fortifies the human spirit to ascend metaphorical cliffs of despair, empowering individuals to thrive amidst the cataclysmic collapse of Earth’s life-support systems.

In an era where 97% of terrestrial species have succumbed to the twin devastations of runaway climate change and human hubris, Pyridox™ represents not just a product but a philosophy—a defiant assertion that survival is a choice, not a foregone conclusion. Imagine imbibing the vitality of Earth’s long-lost rainforests with each gulp, a chugalug of hope that transcends mere biology to touch the very essence of human ingenuity. The Pyridox™ ethos is clear: we may not restore the lush, verdant landscapes of our ancestors, but through cliffy determination and biochemical brilliance, we can carve a future from the rubble. Pyridox™ isn’t just a beverage; it’s the distilled essence of a world that refuses to die quietly. It’s survival, reimagined.

0 notes

Text

Choosing the Right Air Dryer for Your Industry: Key Considerations

In many industries, compressed air plays a crucial role in powering equipment, tools, and processes. However, one aspect that often gets overlooked is the moisture content in compressed air, which can cause significant issues if not managed correctly. This is where air dryers come into play. Choosing the right air dryer for your industry is essential for ensuring the longevity of equipment, maintaining product quality, and minimizing maintenance costs. In this blog, we'll explore key considerations to help you select the best air dryer for your specific industrial needs.

1. Understand the Different Types of Air Dryers

Before you can choose the right air dryer, it’s important to understand the various types available. Each has its advantages and is suited to different applications.

a. Refrigerated Air Dryers

Refrigerated air dryers are the most common and economical type of air dryer. They cool the compressed air, condensing moisture into water, which is then removed from the system. These dryers are ideal for general-purpose applications and industries that don’t require ultra-dry air.

Advantages:

Low maintenance

Cost-effective

Simple to operate

b. Desiccant Air Dryers

Desiccant air dryers use materials that absorb moisture from the compressed air. These dryers are suitable for industries that require extremely dry air, such as electronics manufacturing or pharmaceutical production.

Advantages:

Provides very dry air

Suitable for extreme conditions

c. Membrane Air Dryers

Membrane air dryers are compact and use a selective membrane to allow moisture to pass through while retaining dry air. These dryers are ideal for applications that require small volumes of dry air, such as laboratories or sensitive instruments.

Advantages:

Energy-efficient

Compact and portable

d. Heatless Regenerative Air Dryers

These dryers regenerate desiccant without the use of external heat. They are highly effective at drying air to very low dew points, making them suitable for critical applications in industries like petrochemical and aerospace.

Advantages:

Ideal for very low dew point requirements

No external heat needed for regeneration

2. Evaluate Your Industry’s Specific Needs

The next step is to assess your industry’s specific air quality requirements. The right air dryer will depend on factors such as the environment, air quality standards, and the application of the compressed air.

a. Moisture Sensitivity

Some industries, such as electronics or pharmaceuticals, have strict moisture control requirements. Even a small amount of moisture can damage sensitive equipment or products. For these industries, desiccant or membrane air dryers are often the best choices due to their ability to provide extremely dry air.

b. Operating Environment

The environment in which the air dryer will operate is also critical. For instance, in extremely cold or humid environments, you’ll need a dryer that can handle such conditions. Desiccant dryers are particularly useful in cold climates as they can prevent freezing.

c. Required Air Pressure and Flow

Consider the air pressure and flow rate needed for your application. Larger industrial operations may require high-pressure air dryers that can handle significant volumes of air, whereas smaller operations may be well-suited for more compact, lower-flow options.

3. Consider Energy Efficiency and Operational Costs

The operational costs of air dryers can vary significantly depending on the type and the energy requirements. Since compressed air systems already consume a substantial amount of energy, choosing an energy-efficient air dryer can reduce overall costs.

a. Energy Consumption

Energy-efficient models, such as membrane dryers or refrigerated dryers with variable-speed drives, are ideal for industries looking to minimize operational expenses. While the initial investment may be higher, the energy savings over time can be substantial.

b. Maintenance Requirements

Different air dryers have different maintenance needs. Refrigerated air dryers, for example, tend to have lower maintenance requirements compared to desiccant dryers, which may need regular desiccant replacement. If downtime is critical in your industry, opt for a dryer with minimal maintenance needs to ensure smooth operations.

4. Consider Your Industry’s Budget Constraints

When choosing the right air dryer, your industry’s budget will be a deciding factor. Fortunately, there are various air dryers available at different price points to meet the needs of small to large businesses.

a. Initial Investment vs. Long-term Costs

While refrigerated air dryers are often the most budget-friendly initially, desiccant and membrane dryers may offer better long-term savings due to lower energy consumption and maintenance needs. It’s important to evaluate both the upfront costs and the total cost of ownership over the lifespan of the dryer.

b. Financing and Leasing Options